Robotic workstation in harsh environmental conditions to improve safety in the steel industry (ROBOHARSH)

Research area Innovation and education in the digital society | Antonius Johannes Schröder | Beata Lewandowska

ROBOHARSH is combining technological innovation with a social innovation process by installing a robotic cell in the steel shop supporting technical personnel in the control of the tap hole, replacing the sliding gate and related refractory material at the bottom of the ladle.

European Union - Research Fund Coal and Steel (RFCS)

The aim of ROBOHARSH is to demonstrate on the basis of a real installation that the occupational safety of workers in a steel mill can be improved if an industrially usable robotic cell supports technical personnel in the maintenance of ladle slides by replacing human intervention in difficult and potentially dangerous operations. This robotic application differs significantly from applications previously known in the steel industry, as the approach of symbiotic human-robot cooperation is realized to master complex tasks under harsh environmental conditions.

The overall goal of the project is to develop a robotic workstation in which human operators and an industrial robot actively cooperate to handle most of the upcoming maintenance activities on the ladle slide. Specifically, the objectives are as follows:

- Develop a complete cell with an industrial robot capable of safely interacting with a human operator by having the robot assist the operator in the most difficult maintenance activities on the ladle slide;

- Developing a vision system that is applicable in the harsh environmental conditions of the steel mill and helps control the robot. This is done by having the system provide the information needed to complete the task and to ensure that operators always have a complete overview of all activities;

- Deep study of ergonomics in the workplace through modeling, simulation, and through ergonomics evaluation methodologies to make the interaction between the user and the robot not only safe, but also easy and natural;

- Development of an approach for ad hoc training for personnel working in the (robot) cell. This is not only about learning the application procedures properly, but also about motivational aspects. Therefore, the training is also a way to re-qualify, aiming to improve the skills and abilities of the users involved;

- In-depth study of the social and psychological aspects of a symbiotic human-robot interaction in an environment that is very different from what is usually found in the manufacturing industry.

- Scuola Superiore Sant'Anna (SSSA)

- Polytec s.r.l. (POLYTEC)

- ILVA Spa

- Technical University of Dortmund - Social Research Center (TUDO)

- PSC Automatizari si Instalatii SRL

The development of a robotic workstation is started by defining the system requirements and creating a list of operations that can be performed by the robot. Then, design and special requirements of this application are developed, as well as control and monitoring routines. After the integration of the workstation into the production process, testing, validations and adjustments are carried out. Central to this is the integration of technological development into a social innovation process that integrates the relevant actors and areas from the beginning (production process, management, organizational and human resources development). Social aspects such as qualification and work changes as well as the final evaluation and assessment of the performance and functionality of the system, also and especially with regard to health and safety, form the conclusion of the project.

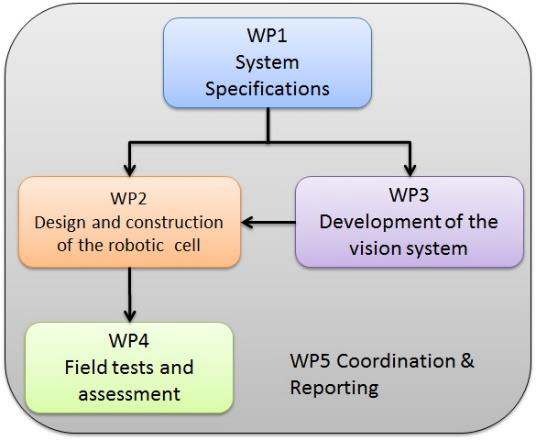

The methodological approach of ROBOHARSH focuses on the combination of technological innovations with a social innovation process, which not only takes the technological perspective on innovations, but also includes the perspective of end users/users, which enters into a co-creation process. In addition, an assessment of the social impact of innovations is carried out from the outset. The overall work program is divided into five work packages:

Work Package 1 System Specifications: Define the basic requirements for the robotic workstation by including the selected application and work environment. A modeling and simulation study will also investigate the ergonomics of the work position. A list of quantitative Key Performance Indicators (KPI) will be developed to evaluate the validity of the developed system and its benefits compared to current manual practice.

Work Package 2 Design and Construction of the Robotic Cell: In this work package, the robotic cell will be fully designed and implemented - including the end effectors (tools and grippers), which will be designed ad-hoc for specific tasks. The entire system (including the vision system) will be integrated and preliminarily tested in the POLYTEC factory, while the steel plant personnel, who will follow the field test, will undergo training. At the same time, the operational environment in the steel plant will be prepared for the installation of the robotic cell. Maintenance issues will be included at this stage as an integral part of system reliability.

Work package 3 Development of the vision system: The vision system with which the robotic cell will be equipped will be developed in all its components, and the robot's control system will be adapted for this purpose. A local monitoring system and a remote monitoring system will also be developed here to monitor the robot cell by the local technical staff and by the developers from their respective premises. This will serve for continuous performance monitoring, functional testing and easy as well as fast problem solving, especially during the field test phase. This work package will be developed in parallel with work package 2, as the vision and monitoring system will need to be integrated into the robotic cell, which will be assembled and preliminarily tested during the final tasks of work package 2.

Work Package 4 System Integration and Field Testing: The robot-assisted workstation will be installed and tested in the field. This testing phase can be divided into two sub-phases, according to the 2-level list of tasks in Work Package 1. In particular, the first tests aim to preliminarily verify the robustness and reliability of the system. This will be done by executing the first sub-list of tasks, while the second series of tests aims at evaluating and ensuring the full operational capability of the robotic cell - also with respect to the second list of tasks described in Work Package 1. ILVA will install the robotic cell in its own steel plant. A significant role in this work package is played by the study of the social aspects of the introduction of the robotic cell in this particular professional environment. The special aspect of this robotic application lies in the extensive cooperation between the user and the robot, as well as in the human-machine interface, which must be developed in such a way that users can use their experience, sensitivity and control ability to be able to control the robotic activities. This is absolutely necessary to perform the complex and non-repetitive operations required in the replacement of a ladle slide. Therefore, system performance will not be evaluated only in terms of technical conditions; rather, user acceptance will also be included (especially in terms of perception of one's professional role, growth in skills and abilities, and other professional aspects). The sociological analysis will support the development of training courses for the technical personnel who will operate the robot-assisted cell. A final evaluation will also include evaluation against KPIs defined in Work Package 1. They include quantification of fundamental aspects such as improved occupational safety for employees, reduction of occupational accidents, and the reliability of the ladle sliders.

Work package 5 Coordination and reports: This work package is a cross-cutting task and is dedicated to reporting and coordinating the research activities.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/a/f/csm_Kontakt_b86e8d8ecc.png)

![[Translate to English:] [Translate to English:]](/storages/sfs-sowi/_processed_/6/c/csm_Glasfront_sfs_Header_eae6d325d3.jpg)